- ホーム

- >

- 製品

- >

- Tungsten Carbide Strips

- >

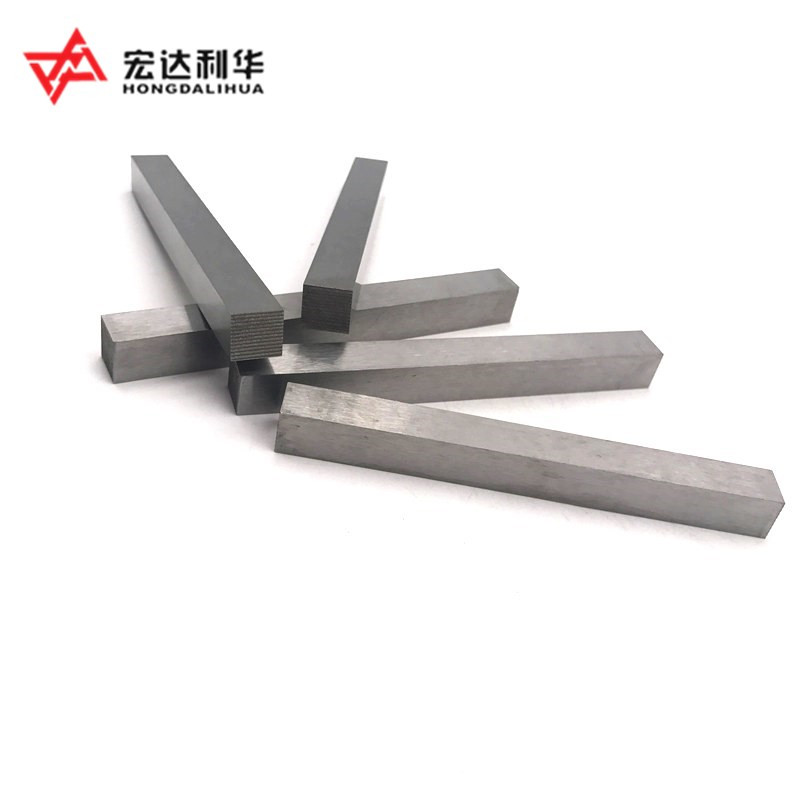

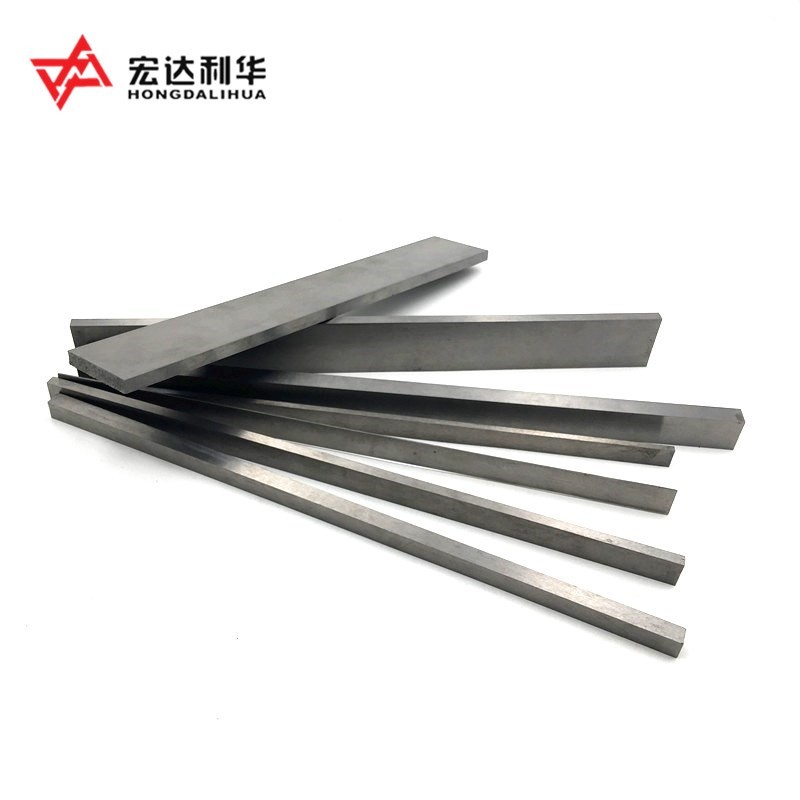

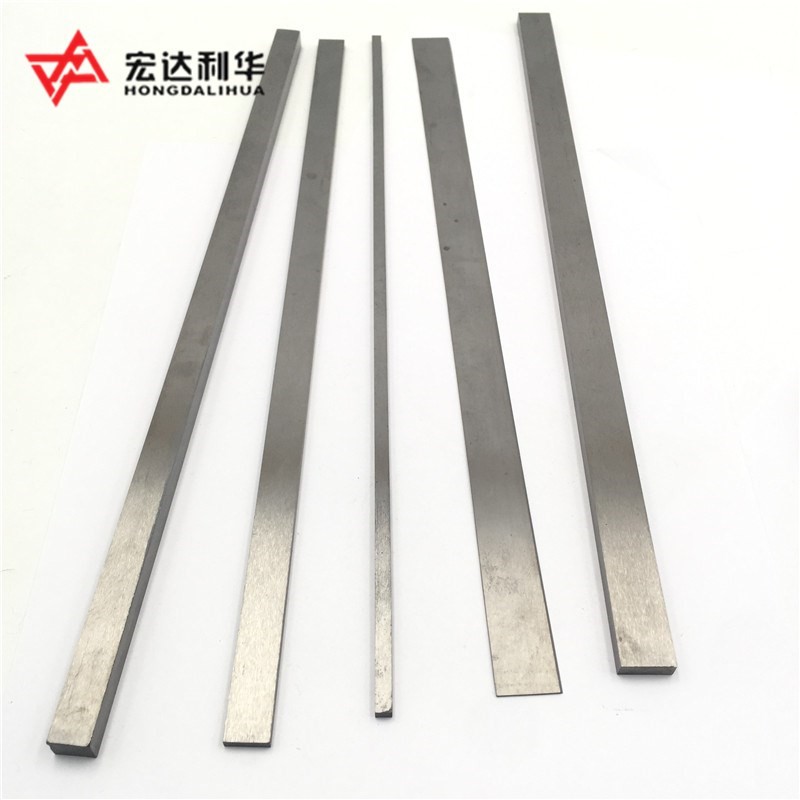

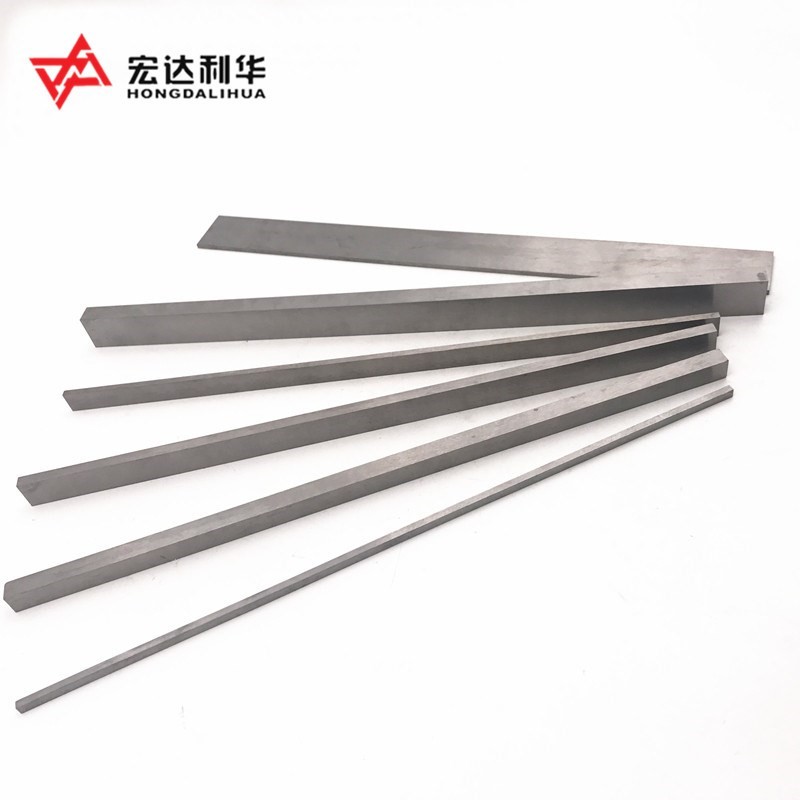

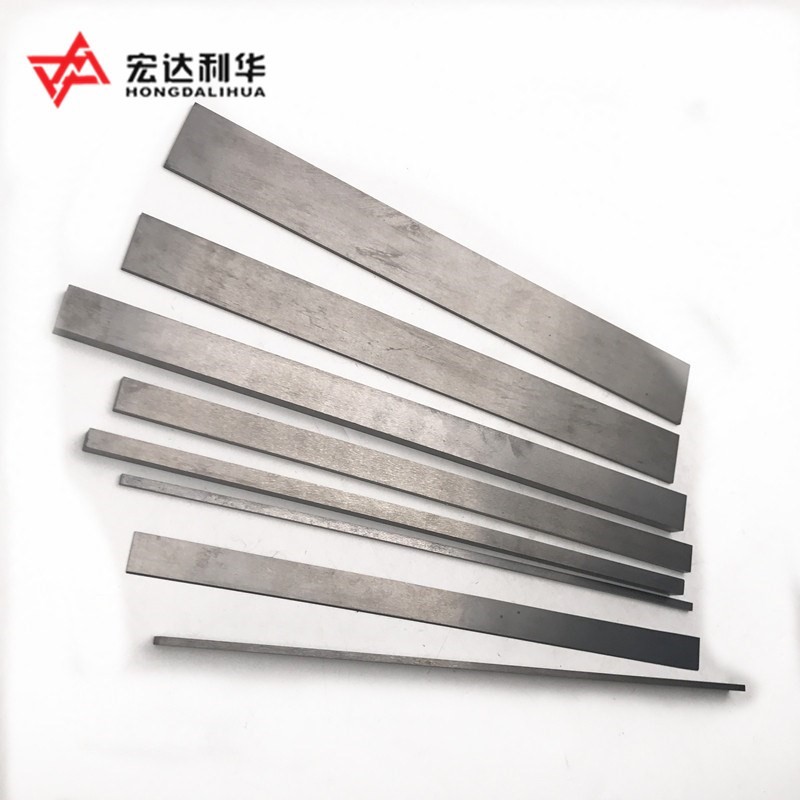

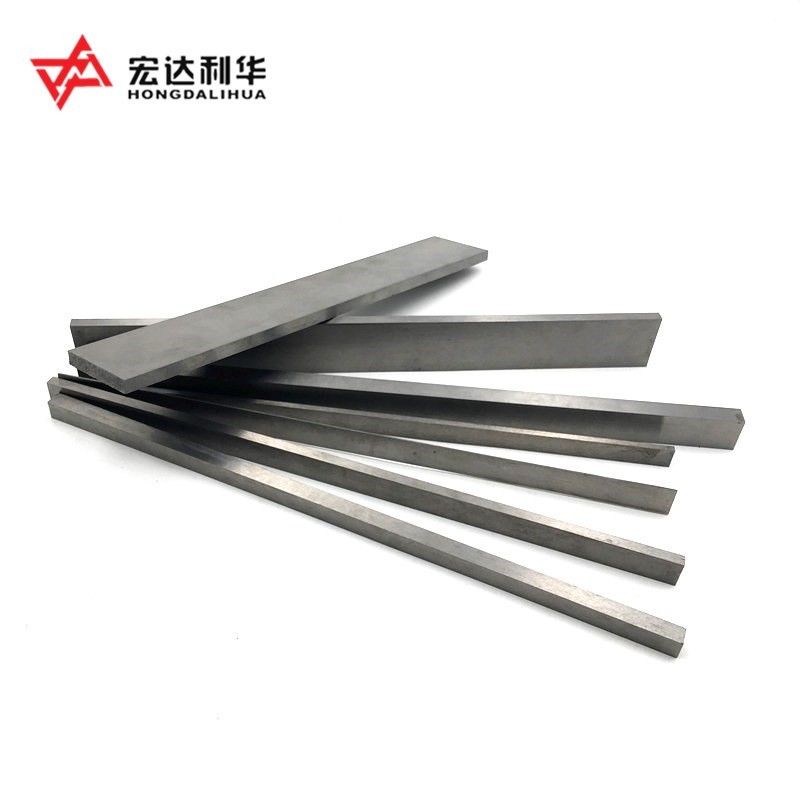

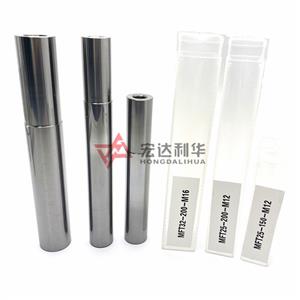

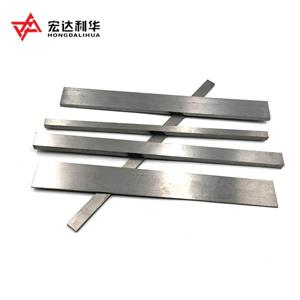

- Carbide Strip Blade Type Cutting Machine Spare Parts

Carbide Strip Blade Type Cutting Machine Spare Parts

ブランド :Lihua

製品の産地 :Zhuzhou, China

納入時間 :7-15 Working Days

供給能力 :15 Ton per Month

L <100(0~ + 1.0)

320

L≧100(0〜+ 2.0)

L = 320(0~ + 5.0)

1.5×(2〜10)×L

2.0×(3.5〜15)×L

2.5×(3.5〜20)×L

3.0×(3.5〜20)×L

3.5×(3.5〜25)×L

4.0×(4.0〜30)×L

5.0×(4.0〜40)×L

6.0×(5.0〜40)×L

(7〜20)×(7〜40)×L

(10~30)×(20~40)×L

Tungsten k10&k20 carbide bar/strips for wood&metal cutting

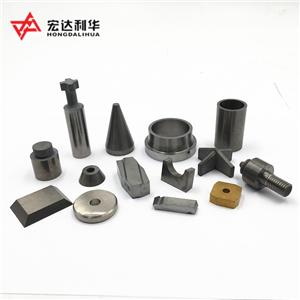

Grade, Properties and Applications of Carbide for Strip

Grade | Density | T.R.S (MPa) | Hardness (HRA) | Performance & application recommended | ISO |

YG6 | 14.8 | ≥2150 | ≥90.0 | High wear resistance, used for hard wood, used for processing original wood, aluminum section bar, brass rod and cast iron. | K20 |

YG6A | 14.9 | ≥1860 | ≥92.0 | Better wear resistance than YG6, used for processing hard wood, original wood , aluminum section bar, brass rod and cast iron. | K10 |

YG8 | 14.8 | ≥2320 | ≥89.5 | Wear and percussion resistance, used for processing hard wood, soft wood, ferrous and non-ferrous. | K30 |

YS2T | 14.8 | ≥2350 | ≥92.0 | Fine grain carbide, high wear resistance , high bending strength, high resistance to bonding, high thermal. Machining of refractory alloys, stainless steel and high manganness steel, etc. | M10 |

YS25 | 13.8 | ≥2200 | ≥91.0 | Carbide grade with high hardness and good wear-resistance, suitable for rough turning, milling and planing of carbide steel, cast steel, high intensity steel and steel alloy. | P25 |

YL10.2 | 14.5 | ≥2150 | ≥92.2 | Wear resistance and strength comparatively higher, suitable for processing cast iron, non-ferrous and non-metal , materials. | \ |

Dimensions of Tungsten Carbide Strips | |||

Unit (mm) | |||

Type (T×W×L) | Tolerance of T | Tolerance of W | Tolerance of L |

1.0 ×(2~5) × L | 0.2~0.6 | 0.2~0.6 | L<100 (0~+1.0) 320>L≥100 (0~+2.0) L=320 (0~+5.0) |

1.5×(2~10) × L | |||

2.0 ×(3.5~15) × L | |||

2.5 ×(3.5~20) × L | |||

3.0 ×(3.5~20) × L | |||

3.5 ×(3.5~25) × L | |||

4.0 ×(4.0~30) × L | |||

5.0 ×(4.0~40) × L | |||

6.0 ×(5.0~40) × L | |||

(7~20) ×(7~40) × L | |||

(10~30) ×(20~40) × L | |||